Centrifugal Pump Mechanical Seal

Product details

Centrifugal Pump Spare Parts Mechanical SealCentrifugal pump spare parts mechanical seal is an essential component installed and utilized in pump equipment. Its primary function is to provide dynamic sealing, effectively preventing the fluid medium within the pump volute from leaking through the pump shaft.

Centrifugal Pump Spare Parts Mechanical Pictures

Centrifugal Pump Spare Parts Mechanical Seal Material

Centrifugal Pump Spare Parts Mechanical Seal MaterialHastelloy, 1Cr18Ni9Ti, 3Cr13

Centrifugal Pump Spare Parts Mechanical Seal Features1. Good sealing performance: the mechanical seal can effectively seal the medium in the pump equipment to prevent leakage and pressure relief.

2. High wear resistance: Since pump equipment is subjected to high-speed rotation and friction during work, mechanical seals are usually made of wear-resistant materials to ensure long-term use and durability.

3. Strong adaptability: Mechanical seals are suitable for all kinds of pump equipment, whether it is centrifugal pumps, screw pumps or other types of pumps, mechanical seals can be used to ensure effective sealing.

4. Simple maintenance: Mechanical seals usually adopt a modular design, which is easy to install and replace. Maintenance personnel can perform repairs and replacements quickly, reducing downtime.

5. High temperature and high pressure performance: The mechanical seal can withstand working conditions under high temperature and high pressure environment, ensuring the safe and reliable operation of pump equipment.

6. Adapt to a variety of media: Mechanical seals are suitable for a variety of liquid media, including corrosive media, high-viscosity media, and media with high solid particle content, such as mortar in centrifugal pumps.

Centrifugal pump leakage point:1. Seal between the sleeve and the shaft

2. Seal between the moving ring and the shaft sleeve

3. Seal between dynamic and static ring

4. Seal between static ring and static ring seat

5. Sealing the seal between the end cover and the pump body.

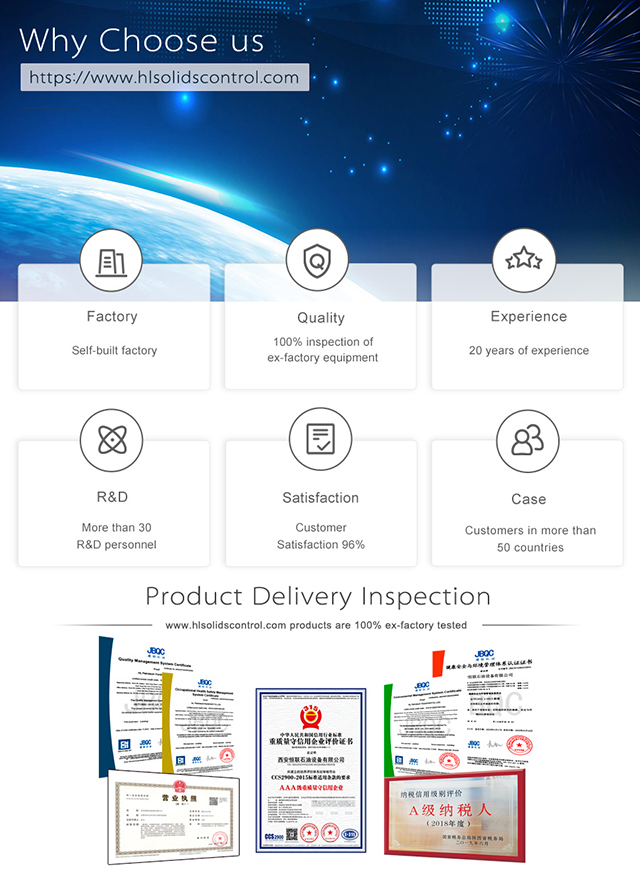

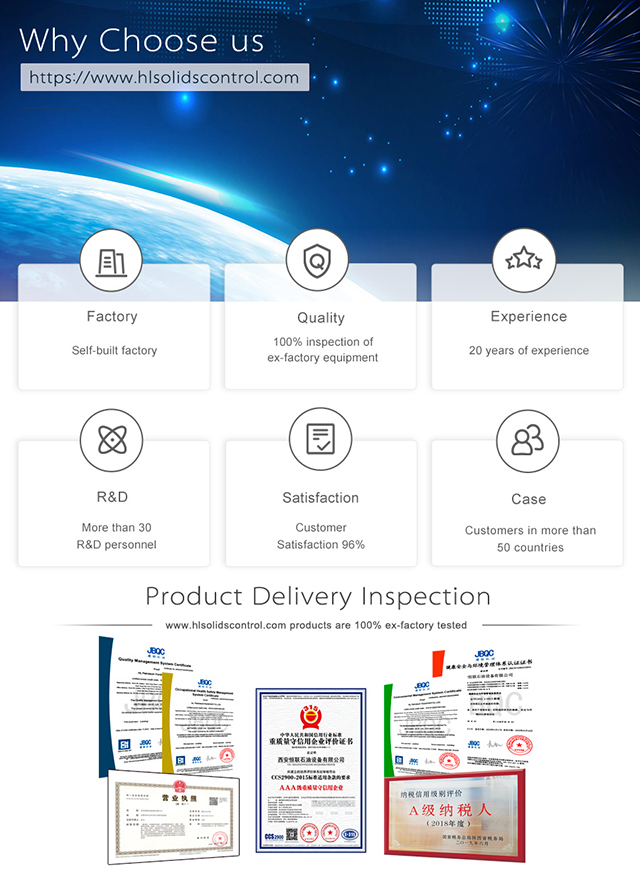

Why choose us?

HL Factory

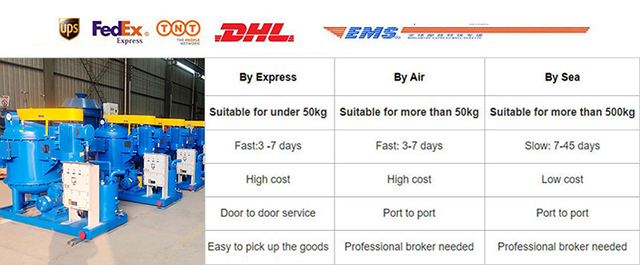

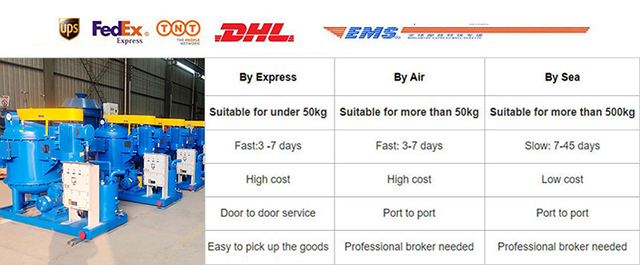

About Shipping